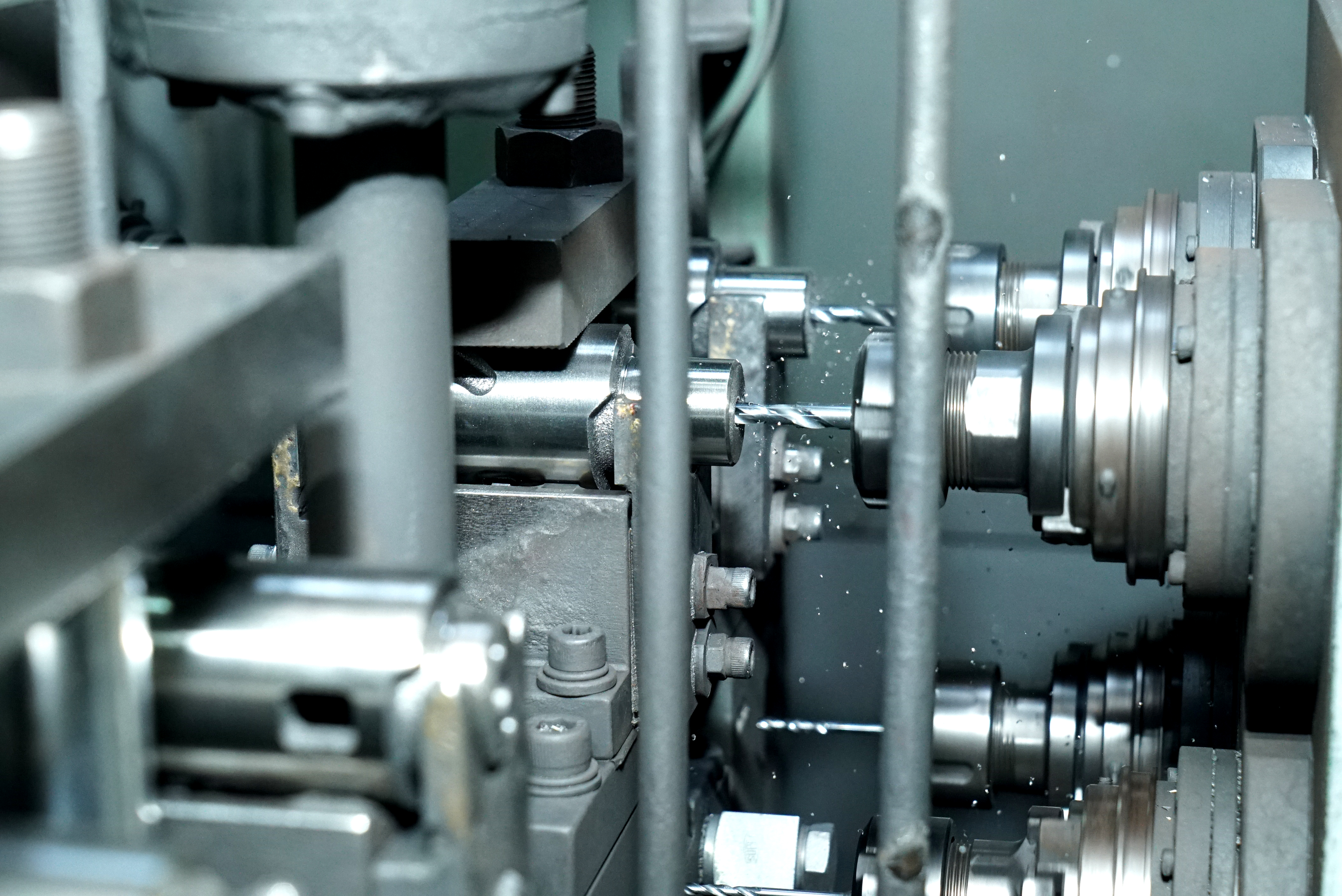

Our modern machine shop is equipped with the latest CNC, VMC, HMC, and specialized grinding machines for high-precision component manufacturing. Over 80% of our machines are imported, ensuring global standards in performance and reliability.

We have world-class machine shop facilities, featuring semi-automated systems, climate-controlled environments, and advanced Industry 4.0 capabilities to ensure precision, efficiency, and innovation in every process.

We boasts world-class machine shop facilities, featuring semi-automated systems, climate-controlled environments, and advanced Industry 4.0 capabilities to ensure precision, efficiency, and innovation in every process.

ET Group boasts world-class machine shop facilities, featuring semi-automated systems, climate-controlled environments, and advanced Industry 4.0 capabilities to ensure precision, efficiency, and innovation in every process.

5,000 MT/Year

Up to 900 × 700 × 1000 mm

5–100 kg

1,200 MT/Year

Up to 10 lbs

150T – 500T

To uphold its exceptional quality standards, ETG operates cutting-edge laboratories providing comprehensive Metallurgical and Metallurgical Testing Capabilities for Raw Materials, In-process, and Finished Parts. Our certified team members are equipped with the latest technological expertise and best practices to deliver top-notch quality products to our customers.

Dimensional & Geometric Accuracy

Material & Metallurgical Validation

Cleanliness & Process Reliability

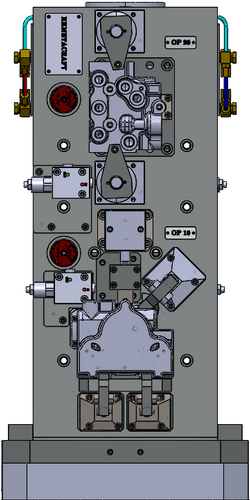

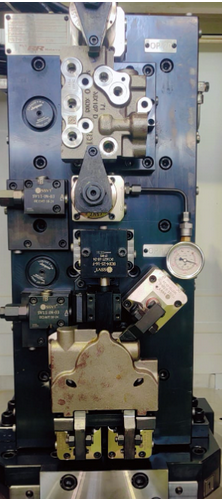

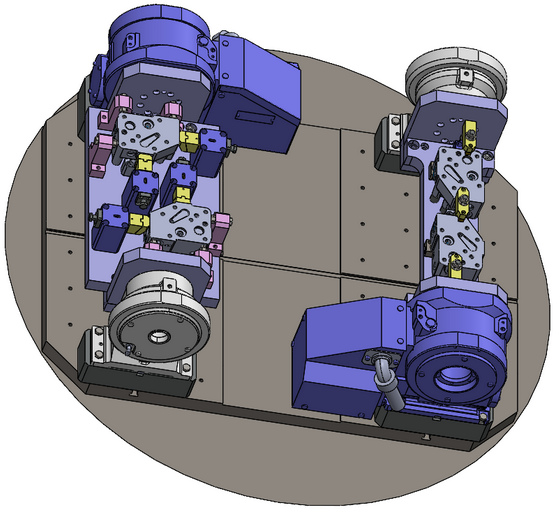

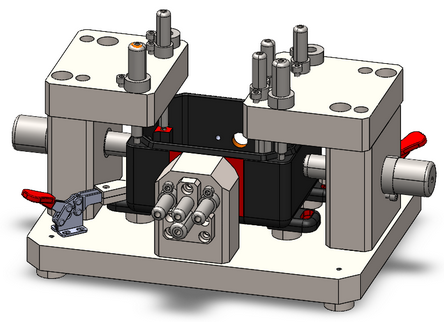

ET Group develops and integrates proprietary automation solutions that enhance process capability, strengthen quality outcomes, and optimize operational costs. Our R&D, machine design, and fixture engineering teams collaborate to ensure seamless, efficient, and scalable manufacturing performance.

Our advanced machining ecosystem combines next-generation CNC technology with robotic automation to deliver exceptional precision and 24/7 production reliability.

At ET, we specialize in the design and manufacture of high-precision fixtures tailored to meet the demands of various industries including automotive, aerospace, electronics, and medical devices. Each fixture is engineered to ensure accuracy, repeatability, and ease of use—helping our clients streamline production and achieve consistent quality.